Our experts help the clients to increase their asset value. Some of the techniques used are as follows:

-

Reservoir Modeling/Simulation

-

Enhanced Oil Recovery(EOR)

-

Unconventional Resources (Shale & Tight)

-

Reserve Evaluation & Audit

-

Oil & Gas Economic Evaluation

-

Integrated Field Development and Reservoir Studies

-

Production Forecasting

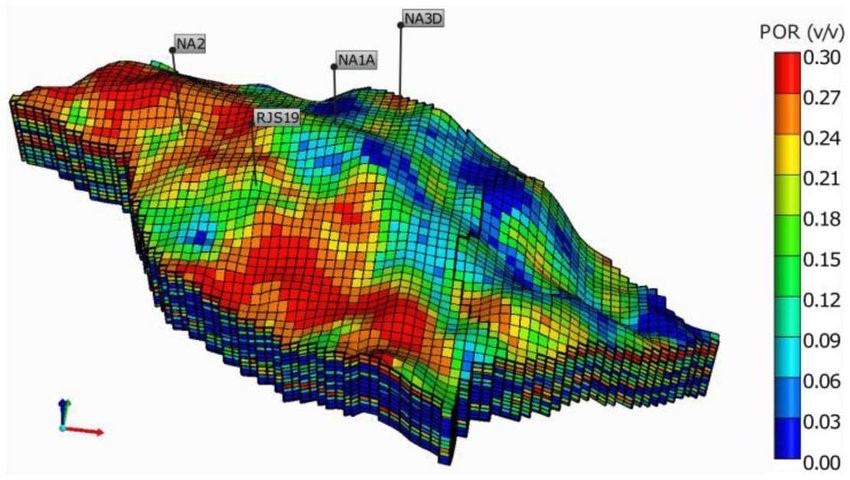

Reservoir Modeling/Simulation:

From appraisal to abandonment nearly every type of field-production scenario can be modeled. A reservoir simulation model is a tool that helps E&P companies make informed business decisions in a variety of oil and gas projects including but not limited to reserves estimates, reservoir management, reservoir performance, enhanced recoveries, process design and strategic planning. No other tool can capture the many facets of reservoir behavior affected by heterogeneity, well interference, material balance and wellbore dynamics.

Your problem may be to develop reserves, identify infill drilling opportunities, design or optimize a pressure maintenance/enhanced oil recovery program, determine efficient well spacing, evaluating changes to processing facilities or improving gas-storage operations. Whatever the case, our team of experts constructs and executes simulation models to provide you insight and help you devise development or operational strategies to maximize recovery and profit. These build-for-purpose models predict the performance of straight, horizontal/directional wells and wellbore tubulars linked to the surface, well patterns, sectors of fields and even entire fields using our super fast and powerful high performance computers.

-

Black Oil, Compositional, Chemical, Streamline Simulation

-

Simulation Workflow: Build/Run/Calibration/Troubleshooting

-

Model-Based History Matching

-

Experimental Design

-

Integrated Production Modeling

-

Characterization and Geostatistics

-

4D Seismic (Sim2Seis) and 4D CSEM (Sim2EM) Feasibility Studies

-

Coupled 4D Seismic and Reservoir History Matching

-

Coupled 4D CSEM and Reservoir History Matching

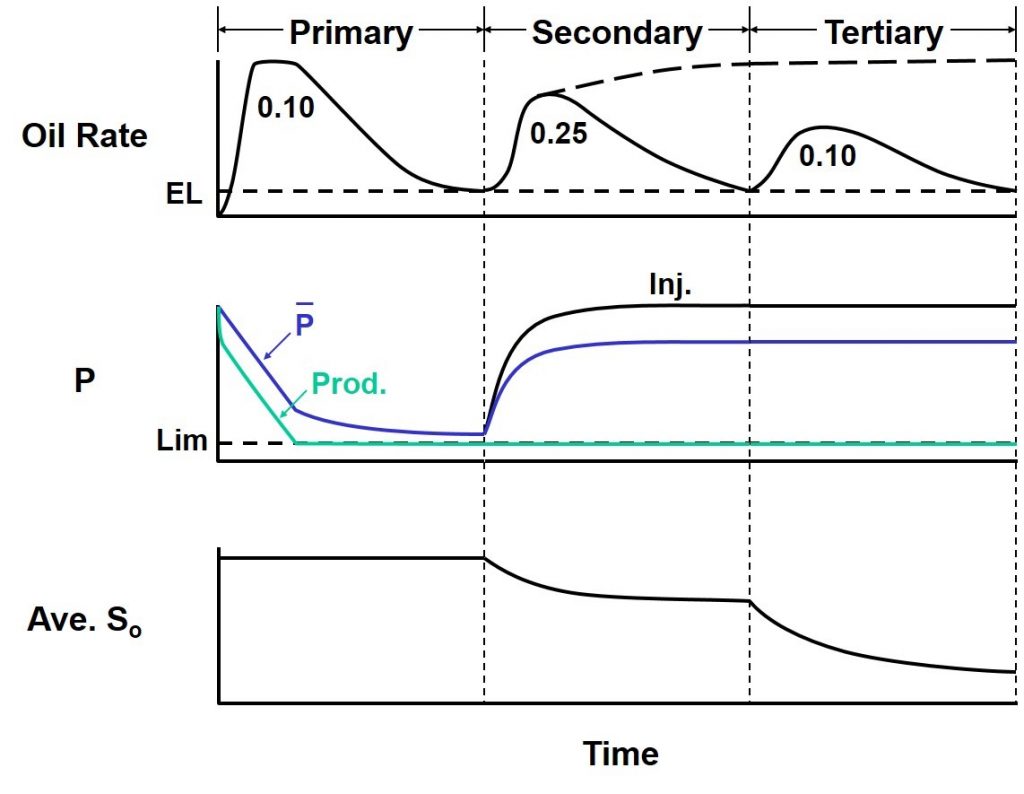

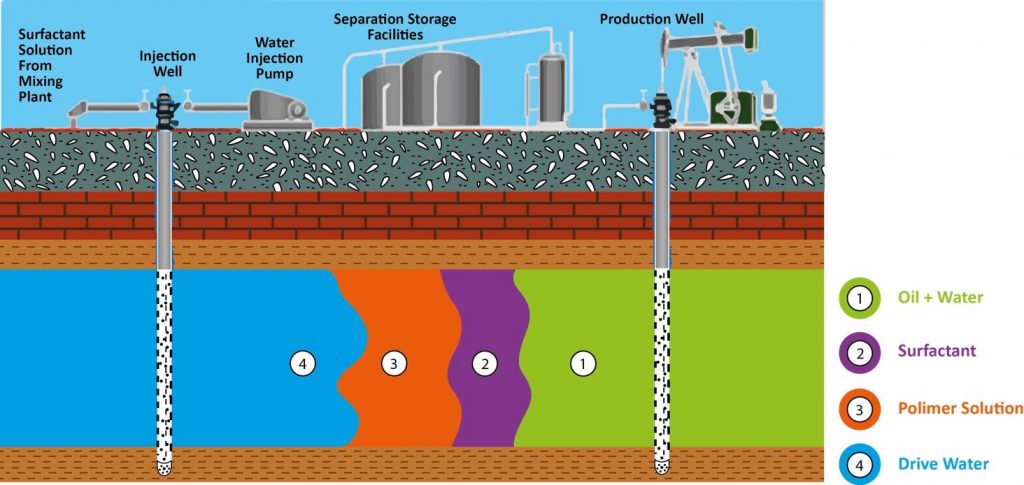

Enhanced Oil Recovery (EOR):

As countries develop, industry and higher living standards drive up energy use, most often of oil. This justifies the world’s increasing demand for crude oil and motivates the oil producers to increase the oil recovery or explore for new oil fields. Exploration of new oil resources has not found enough hydrocarbons to compensate for the depletion of the producing fields and increasing demand of world crude oil. In addition, developing new fields (also called green fields) suffers from huge capital costs and being very time consuming. Therefore, increasing the oil recovery using pressure maintenance (waterflooding and gas injection) and enhanced recovery methods, also called EOR, is vital to meet the increasing world crude oil demand and counterbalance the inevitable oil production decline rate. Today, oil production from EOR processes supplies a considerable amount of the world’s oil production.

EOR methods are basically classified as:

-

Gas Flooding Methods (including HC gas, CO2, Nitrogen, etc.)

-

Chemical Flooding Methods (including polymer, surfactant-polymer and alkaline-surfactant-polymer)

-

Thermal Methods (including steam and insitu-combustion)

In APG, we perform all stages of pressure maintenance and EOR projects study and design from screening and feasibility studies to experimental studies and lab tests, furthermore from modeling and numerical simulation to actual pilot and field planning. Our experts are capable of fast screening and prediction of preliminary results based on analytical predictive tools for feasibility studies of a single reservoir or reservoir asset. A typical study that may take 1-2 years, will be performed in a few months because of the substantial direct experience and outstanding skills available at APG.

Production phases

ASP (Alkali Surfactant Polymer) Flooding

Unconventional Resources (Shale & Tight):

Unconventional Resources refers to the oil and gas resources that cannot be developed and produced by conventional processes; using the natural pressure of the reservoir and pumping or compression operations. Because of the specific conditions of these resources (e.x. very low permeabilities and poor reservoir properties), production is typically more costly that conventional resources. It wasn’t before 2000s that the oil and gas prices started to increase slightly and long term perspectives were indicating that they would not come down soon. Therefore development of unconventional resources and research in these areas came to attention oil & gas companies specifically after invention of hydraulic fracturing. Today, unconventional oil and gas are the global energy game changer.

APG plays a leading role in consulting to oil E&P companies. The technical works usually aim for:

-

Integrated field development

-

Fracture design and optimization

-

Well planning and well space optimization

-

PVT analysis

-

Rate-transient analysis including modeling transient- vs. boundary-dominated flow

-

Numerical simulation

-

Flowing material balance analysis

Reserve Evaluation & Audit:

Reserve is referred to the technically and economically recoverable part of the reservoir hydrocarbon in place estimated based on current and planned wells production. Whatever method is used in estimation it must be comprehensive and reliable because of the importance of this estimation in subsequent calculations and managerial decisions. For this purpose, in APG we use combination of different methods including volumetric methods, well performance, rate transient and decline curve analysis, material balance, simulation and analogue data. The outcomes of this technical and economical evaluation are estimated reserve numbers, future production rates, production cash-flow, discounted net present value and expected net income depending on the client desires. In APG we usually generate the estimations under a variety of scenarios considering different expected future prices, operating and capital costs. This knowledge and experience is also used for auditing the reported reserve by reviewing the data and interpretive geological and reservoir engineering procedures to provide our clients with a technical opinion about the reasonableness of the reserve estimations and accuracy of the methodologies.

Oil & Gas Economic Evaluation

What matters in decision making of a project whether it is development of a new (green) field, deployment of an EOR project or even doing additional completions on wells is not the amount (volume) of the oil produced but the economy and commercial reasonableness of the project. Therefore, financial analysis of the project/s is of great importance to consider and study the involvement of income, costs and inflation over time. At APG we test and integrate a variety of economic scenarios into models to evaluate relative effects. This is to analyze and understand how projects pay out under various, complex production-sharing contracts and concession and service agreements. Economical analysis is based on discounted cashflow (DCF) valuation models that allow for the input of various production/cost scenarios and customizing for meeting the complexities involved in each case.

Integrated Reservoir Studies and Field Development:

Field development consists of prediction of the future performance of a reservoir under specific constraints for the purpose of optimal development planning recommended by specialists. The process starts with screening of the reservoirs, identifying & prioritizing the best candidates, recommending the target reservoirs for more detail reservoir studies and possible future development. Our team of specialists (usually a team of reservoir engineers and G&G) then estimate the future recoveries and associated cash flow for potential target reservoirs. Reservoir studies provide more knowledge about the target reservoirs and allows technical prioritization for development based on recovery and economics of the project.

Production Forecasting:

-

Data-Driven History Matching Techniques or Analytical Predictive (CRM, TDWF, UTF)

-

Nodal Analysis

-

Simulation

-

Volumetric/Material Balance/Decline Curve Analysis

-

Type Curve Generation

-

Artificial Intelligence

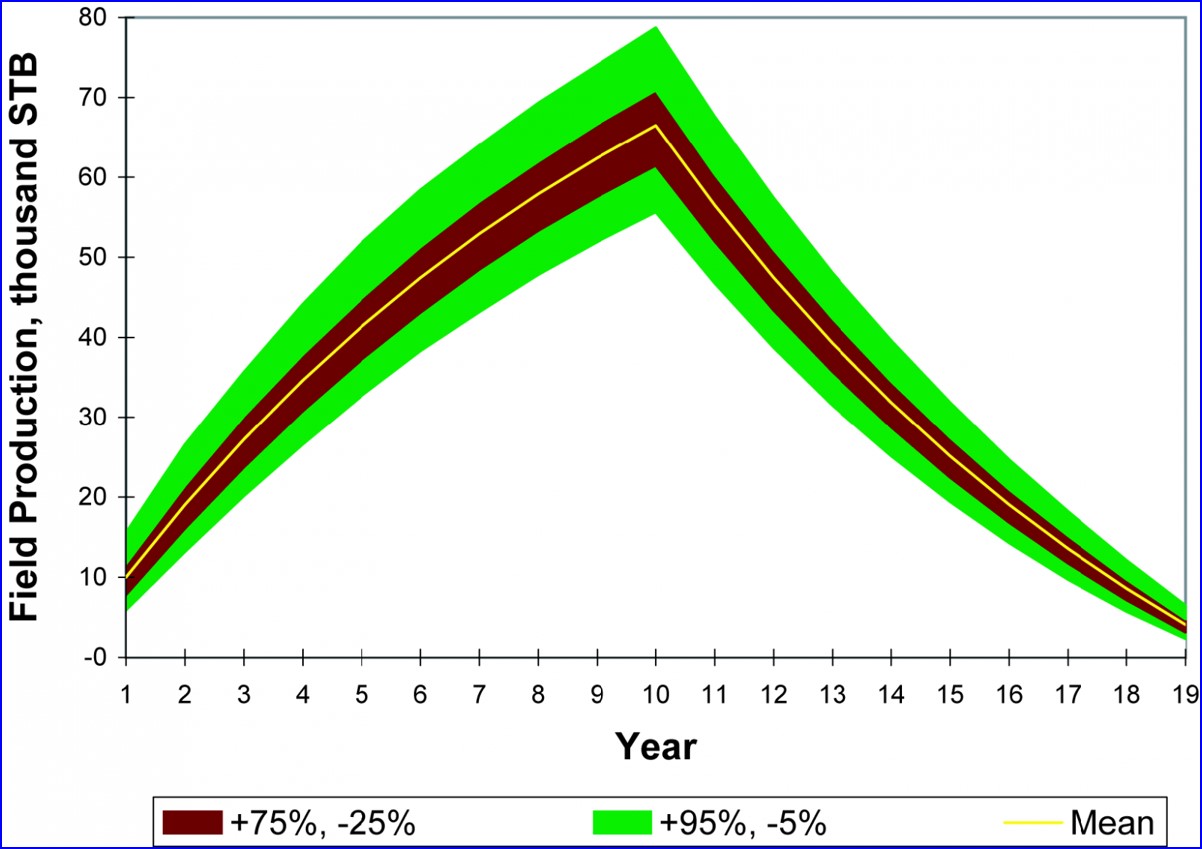

Our experts utilize a wide range of algorithms to forecast field production. In the following some of the methods are summarized:

-

Data Driven Methods:

-

Polynomial Fitting

-

Decline Curve Analysis (DCA)

-

Monte-Carlo Simulation (MC & MCMC)

-

Machine Learning (ML) along with Optimization (GA, SA, PSO)

-

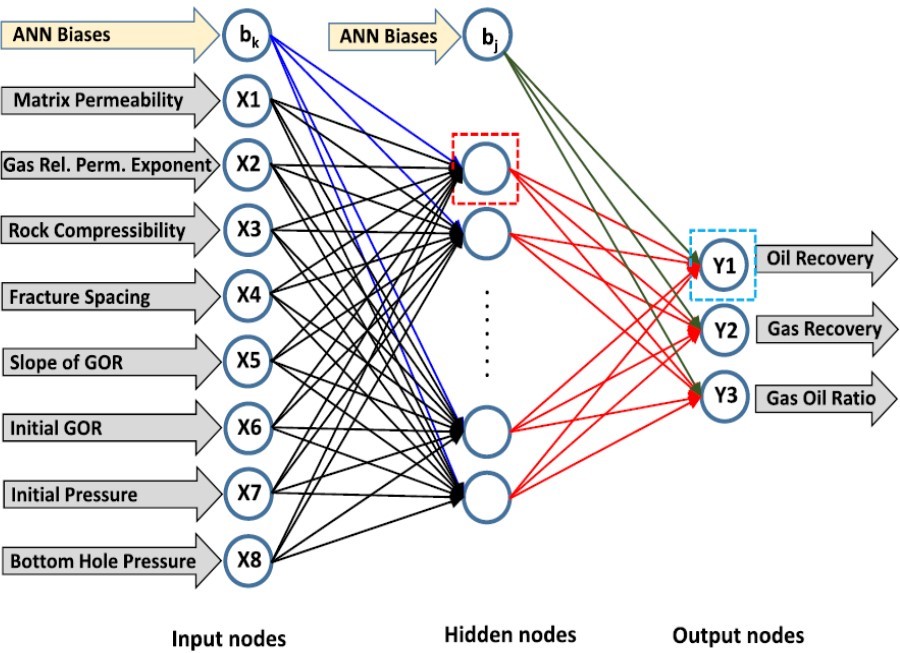

Artificial Neural Networks (ANN)

-

Support Vector Machine (SVM)

-

Bayesian Networks

-

-

Model Based Methods:

-

Analytical Solution of Fluid Flow Equations

-

Numerical Solution of Fluid Flow Equations (FD, FE)

-

Tank Models or Capacitance Resistance Models (CRM)

-

Basic structure of ANN with input, hidden, and output nodes